CONTENTS

-The Proposal

-Overview

-Need statement

-Presidential intervention

-Design and construction of work train

-Design of the electrical grid that will power the railroad

-Design and construction of the concrete poles

-Selecting train routes for overhead electrical power

-Converting locomotives to run on diesel or electricity

-Information sourced from the internet

THE PROPOSAL

Powering the American railroads with electricity is far overdue. Our Present-day railroads are powered by diesel fuel. Almost all modern countries' railroad systems are powered electrically. This includes Japan, all of Europe, Russia, and China. These countries' railroads are not 100% electrified, but they are far ahead of us. The advantages of using electricity to power our railroad systems are many. Environmentally the benefits would be reducing noise pollution, reduction of ground vibration, and reduced air pollution. There are many ways to generate electrical power. Generating electricity by thermal, hydraulic, wind, solar, and nuclear power emits no co2. Having so many different ways to create electrical power will make railroad operations more affordable and flexible. Here in America, we use diesel fuel to power our railroads. If the price of diesel fuel goes up, our operating cost is directly affected. Electrifying our railroad system will not be that difficult. The reason being is that our locomotives are diesel-electric. This means the diesel engine in a locomotive turns a generator that generates electricity. This electricity then supplies the electrical motors that drive the wheels of the train.

The technology to electrify our train system already exists and is used all around the world today. To electrify our railroad we would have to install a power grid, transmission lines above the train tracks, and convert our diesel locomotives to electric. The locomotive is the pulling power of a modern train. Our locomotives today run on diesel fuel. Converting our locomotives to operate on either electricity or diesel will not be difficult. Adding an electrical transformer to the locomotive is all that is needed. The transformer will enable the locomotive to operate on electricity and the locomotive would still be able to operate using diesel fuel if needed. Why are the railroads so important to the United States? Moving freight by rail is the most fuel-efficient form of transportation we have. Freight brought for seaports like Los Angeles, San Francisco, and Seattle will be loaded onto freight trains and delivered to cities across the United States. Once in the city, the freight will be loaded onto trucks and delivered to local merchants. Global warming concerns are real. CO2 levels in our atmosphere are steadily increasing. Any methods to reduce CO2emissions should be seriously considered. Converting our railroads to electric will help reduce CO2 emissions.

OVERVIEW STATEMENT

Electrifying the American railroads is long overdue. The railroads of today operate on only one fuel (diesel). The demand for this fuel has increased, while the supply has decreased. Powering our railroads using electricity has so many advantages. Electricity can be generated in several ways, and that fact makes it more affordable. Electricity is a cleaner fuel and has a lower CO2 footprint. America lacks when it comes to electrically powered railroads. America should be a world leader, and you lead by example. The following proposal will show how to carry out the electrification of the American railroad system. I will focus on, the processes that will be necessary, and the materials that will be needed. Electrifying the railroads will bring our railroads up to world standards. This construction project should generate 100,000 jobs or more.

NEED STATEMNT

Converting a diesel-operative railroad to an electrified railroad system is important for so many reasons. The railroad system in America operated on two main fuels. The first of these fuels was coal which was the sole energy source for locomotives up until the 1930s. After the 1930s steam locomotives were phased out for a new type of train locomotive. The new type of locomotive would operate on diesel fuel. This new type of locomotive would have an internal combustion engine. This engine turns a generator creating electrical power. That electrical power is used by the electric traction motors to turn the wheels of the train. There are three reasons for electrifying the American railroads. Reducing CO2 emissions, Creating Jobs, and anElevatingte our railroad systems to European standards. The need for an all-electric railroad system in America cannot be understated. Delivering power to the train via overhead wires gives us the advantage of also sharing our electrical power with the surrounding communities. Integrating the domestic power grid with the locomotive power grid assures a more reliable power supply for all.

Powering the railroad system using only one type of fuel is foolish. You run the risk of fluctuating fuel costs due to supply and demand. By converting to electricity, fluctuating operating costs diminish. You can generate electricity in several ways, hydroelectric, solar, wind, and tidal generation, to name a few. Carbon dioxide emissions are of great concern due to the fact they are the main contributor to global warming. Converting our railroad systems to be run on electricity would greatly reduce their CO2 footprint. By moving away from fossil fuels to power our locomotive, we free ourselves from a fuel that has a finite supply. As our fossil fuel supplies diminish, the price of fuel will certainly increase. This will make our railroads more difficult to turn a profit. Maintaining a railroad that uses electricity will be less expensive. Great savings will be seen because we will no longer have to maintain the thousands of internal combustion engines that power the train’s locomotives. Converting our US railroad system to operate on electricity will make us equal to the European and Chinese rail systems. To be a true leader of nations, you must lead by example. That is why we must utilize our resources and make the conversion to all-electric railroads inevitable.

PRESIDENTIAL INTERVENTION

Our railroad systems are powered by diesel fuel, and converting them to operate on electricity will be a difficult task. There are about 700 different railroad carriers in the United States. Listing all of them is not necessary, here are some, Amtrak, BNSF Railway, CSX Transportation, Norfolk Southern Railway, Union Pacific Railroad, and on and on. Trying to convince all of these railroad owners to convert to electrical operation would be quite the task. Converting the railroad system to run electricity is long overdue, and should not be put off any longer.

Converting our railroad systems from diesel operations to electrical operations will reduce air pollution and create thousands of jobs. Because the railroads are not owned by any one entity, makes this transition to electrical operation is nearly impossible. I believe the U S President should intervene, utilizing some type of statute or executive power. This intervention would cover all aspects of personal hiring, payroll, and the construction phase of this project. This presidential control would not interfere with or affect any part of the railroad day to day operation. The U S President's only concern would be with the electrical infrastructure and construction needed to convert the railroads to electrical operation. The railroads will provide service for the next thousand years if not longer. They are a vital part of the country's infrastructure and the easiest way to move freight. This is due to a simple fact; rolling a steel wheel on a flat steel track poses the least amount of resistance. The country's infrastructure is vital to our success. Poor planning can lead to disaster, but careful planning can lead to prosperity. Electrifying the American railroads should have started 50 years ago. I believe it's time to start the shift from diesel-powered railroads to electric-powered railroads. Nikola Tesla, wrote this on September 9, 1915. If we use our fuel to get our power, we are living on our capital and exhausting it rapidly. This method is barbarous and wantonly wasteful and will have to be stopped in the interest of the coming generation. There was more to his quote, but I believe he made his point. Electrifying the railroads is one small part of solving global warming. To combat global warming we must attack it on many fronts, and the railroads are just one of those fronts. I know, that anything worthwhile, takes time. And doing the right thing is often difficult. Electrifying the American railroads will be difficult, and will take time.

DESIGN AND CONSTRUCTION OF THE WORK TRAIN

The reason for the work train is to house the crews and the machinery that will construct the electrical infrastructure over the railroad tracks. This would include the support poles, wire support hangers, and the electrified wire that supplies power to the train. The work train would be made up of these components. 1. The locomotive. 2. Electrical generator car. 3. Sleeping car for the construction crew. 4. Flatbed cars for construction materials. 5. Building superintendent's car. 6. Flatbed cars for machinery, tractors, trucks, and all of the machinery. 7. Kitchen, dining, and storage cars. 8. Laundry and shower car for personnel.

The work train concept was designed to mobilize a crew that would work constructing the lines over the tracks. This work train environment will help preserve the safety of the crew and of the people in the small towns they pass through. The work train will be responsible for, the placement of the support pole and overhead electrical line. Work trains will be placed every 30 miles along the chosen route. A work train should be able to complete 30 miles of railroad electrification every 7 to 10 work days. Four work trains working simultaneously should complete 120 miles of track in 10 working days. Guidelines for hiring personnel are most important. At this time, when so many people are out of work, we need to implement a hiring protocol. I believe service veterans and married men supporting families should be our first call. Hiring should be reserved for people without jobs, not persons wishing to transfer from one job to another. Construction of the work train will commence in a train yard. The work train will consist of used train cars, that will be converted to reflect the cars described in the subsequent letter. The sheer scale of this project will require hundreds of work trains to be constructed.

Design of the electrical grid that will power the railroad:

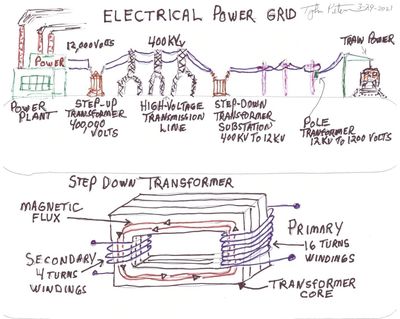

The grid for powering the railroads is basic, the main power supply, transmission stations, substations, and the wire that connects the electric power to the train. The electrical power supply can have many sources and can be generated in many different ways. The source of electrical power could be generated by; wind, hydroelectric, solar electric, thermal power plants, and nuclear power plants. These are all potential sources of electrical power. Power generating and main transmission stations are normally close to one another.

A transformer at the main transmission station increases the voltage from the power plant, to make it able to be sent over long distances. Transformers are used to increase or decrease voltage. The transformer uses electromagnetic induction to make this process possible. Without getting into the physics of how transformers work, let's just say it's magic. Moving down the high-voltage transmission lines, we end up at the electrical substation. The substation uses a transformer to convert the high voltage to a lower voltage. The lower voltage will be delivered to the overhead railroad power lines through power poles that run parallel to the railroad tracks. This lower voltage power will be delivered to the train tracks about every 30 miles apart. On this page, there will be illustrations of power grids and transformers.

Design and construction of the concrete poles:

This section will discuss the design and construction of the concrete poles. The poles will support the high-voltage line that powers the trains. Supplying overhead electrical power to the locomotives requires a great many support poles. An estimated 50 to 100 poles per mile will be needed to supply power to the trains. The distance between the East Coast and West Coast is roughly 2671 miles. If only a single track ran that distance, we would need 112,600 support poles. This amount is needed for just one direct track connecting East Coast to the West Coast. The true amount of support poles needed would be much greater. We need to decide what types of material are best suited for constructing the poles. We have three choices suitable for their construction, wood, steel, or concrete. Wooden poles have a short lifespan and limited supply but are renewal. Steel poles are expensive, and have a longer lifetime, but require constant maintenance. Concrete poles, constructed properly would be more durable, require less maintenance, and would last longer. I believe concrete poles would be the right choice for this application. I designed a technique that will extend the life of concrete poles, and reduce the cost significantly.

I have designed a concrete pole I believe will last for hundreds of years. Before I explain the design characteristics, let me first go back in time to the days of the Romans. About 2000 years ago Emperor Hadrian commissioned the construction of the Pantheon. The building is entirely made of concrete and still stands today. The durability and longevity of This building are due to the absence of steel rebar reinforcement. Steel rebar reinforcement is the strength of concrete, and also its Achilles heel. When steel rebar is penetrated by water, it rust and expands, cracking concrete and causing the concrete to fail. My design for concrete poles differs greatly from other concrete poles or pipes produced today. The concrete poles I designed will not be reinforced with steel rebar or metal wire. Instead, I will use a composite material such as plastic or carbon fiber for reinforcement. Plastic reinforcement rebar materials will be constructed in this fashion. A suitable plastic will be infused with fiberglass for strength.

The plastic/fiberglass material will be extruded through a die in a fishnet pattern. While this extruded material is still malleable, it will be formed into a tubular shape and coated with a material that adheres to wet concrete. Carbon fiber reinforcement rebar would be constructed differently. To construct a carbon fiber rebar we would use several woven carbon fiber ropes fashioned into a fishnet pattern. The woven material will travel over a pipe-like cylinder, to hold its new shape. The new shape material will travel through an annealing oven for hardening. After the hardening process is complete, the carbon fiber rebar will be cut into desired links. To assure a good bond between the carbon fiber rebar and concrete a coding will be applied to the rebar to assure the concrete will adhere to the rebar. To complete the process of making a concrete support pole these steps will need to be taken. Creating a cylinder-shaped mold that is hinged on one side and will allow the other side to be opened. This cylindrical mold will be the length of the concrete pole it is creating. The cylinder mold will be resting in an apparatus that will give it an axial rotation. To create the pole, we will insert the supporting rebar into the cylinder mold. While rotating the mold, we will spray a thin layer of concrete until we reach the desired thickness. At this point, we will replace the concrete spray nozzle, with an inflatable rubber bladder that will extend the length of the pole. The bladder will be inflated to support the wet concrete as it hardens. This technique will also prevent the concrete from drying too quickly.

After the concrete poles have cured significantly, the poles will be removed from their molds. This brings us to the last and most important part of the construction of a concrete pole. Concrete is toughest when it is under compression. Let me explain, if you have a block of concrete 1' x 1' x 1', you could stack 10,000 pounds of weight on top of it, and it would not be damaged. But if you were to pull on either end simultaneously, with as little as 1000 pounds of pressure the block would fail, (be pulled apart). Concrete poles are strongest when they are subject to a compression load. The term compression is often used in concrete construction, referring to a constant load, which can be called preloading. Preloading concrete is usually carried out in this fashion. The section of concrete reinforced with rebar will have small pipes running the length of the concrete. After the concrete has hardened, steel cables will be threaded through the pipes. The steel cables will be anchored at one end; the other end of the cable will be pulled under tremendous pressure and then locked in place. The tension on the steel cable will hold both ends of the concrete together. This action will cause the concrete to be under compression. I intend to use the same principle to apply compression to the concrete poles. Using this technology will make it possible to make concrete poles much taller and stronger. I will demonstrate the process using sketches in the following pages.

SELECTING TRAIN ROUTES FOR OVERHEAD ELECTRICAL POWER

Deciding which sections of track, are to be considered for electrification is decided.

1. How often the tracks are used.

2. What routes are best suited for connecting the city?

3. When prioritizing what routes will be deemed for construction.

4. Communicating with the railroad's owners, concerning what routes would be electrification priorities.

Deciding the routes for electrification and scheduling is most important. Providing this information to the design team assures accuracy when planning construction. For this to happen we will need, clear communication between all parties involved. Proper planning is the key to success in any construction project.

CONVERTING LOCOMOTIVE TO RUN ON DIESEL OR ELECTRICITY

The task of converting locomotives to run on electricity will not be difficult. The modern locomotive operating today is diesel-electric. Diesel-electric locomotive inter-workings consist of a 12-cylinder diesel engine that powers an electrical generator. Electricity generated by the generator powers electric motors that drive the train wheels. Modifying locomotives to operate on overhead electrical power will not be costly. A single transformer is needed for this task. The transformer will convert the high-voltage power delivered to the locomotive, and convert it to low-voltage power. That power will operate the traction motors that drive the train wheels.

The cost of creating all new electric locomotives would be expensive, and unnecessary. Our existing locomotive engines are very heavy. The engine's weight is what helps the locomotives to gain traction when pulling heavy loads. Running on overhead electrical power saves operating the diesel engine. The advantage of converting our existing locomotives to operate on both electric and diesel are many. When overhead power projects have been completed, we operate on electricity. And where there is no overhead power we can operate on diesel fuel to power the locomotive. For those reasons converting our existing locomotives, to run on either electric or diesel makes the most sense.

Additional information sourced from the internet

Why electrifying our railroads is so important.

Freight trains are classified using three different class partitions. These class partitions are based on the amount of income they generate per year. Class, I carriers earn more than $250 million a year. Class 2 carriers are between 20 million and up to 250 million. Class III carriers earn less than $20 million per year. The following illustration depicts which carriers are class I, class II, and class III.

Class 2 carriers are between 20 million and up to 250 million. Class III carriers earn less than $20 million per year. The following illustration depicts which carriers are class I, class II, and class III.

Freight train routes are the most used, with the heaviest traffic.

Foreign Freight Locomotive Programs.

Foreign Freight Locomotive Programs.

Foreign Freight Locomotive Programs.

Foreign Freight Locomotive Programs.

Foreign Freight Locomotive Programs.

The three locomotives featured on this page are electric or dual fuel (Diesel and Electric). These locomotives are manufactured and operated by foreign countries India, Germany, and Japan. America does not have an electric freight rail system or even plans to construct one in the near future. America leads in technology but is far behind freight rail technology.

Foreign Freight Locomotive Programs.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.