CONTENTS

-Overview

-Need Statement

-Design and Construction

-Water PSI

-Windmill Water Pump

-Materials sourced from the Internet

OVERVIEW STATEMENT

Storing renewable electrical energy can take many different forms. We will discuss briefly, five different ways to store electrical power.

1. Pumped Hydroelectric, excess electricity is used to pump water up to a reservoir, and then released to flow down to a generator to create power as needed.

2. Compressed Air, electricity is used to compress air at up to 1,000 PSI and store it in underground caverns. At a later time, the air will be released to a turbine generator to create electricity.

3. Flywheel Energy Storage is a disk with a certain amount of mass that can spin to store energy in kinetic form.

4. Lithium-ion batteries are the best option for home solar panel systems but are not suitable for large power grid applications.

5. Thermal energy storage or TES is normally salt turned to liquid by adding heat. The source of the heat is usually the sun. The stored heat from the liquid salt can be repurposed into electrical energy.

The aforementioned forms of storing energy all have attributes. The type you use depends on your needs, and your environment. I live in California by the coast; it has a mountainous type of terrain. This is an ideal location for Pumped Hydroelectric stored energy. This will be our best choice for California’s coastal energy storage needs.

NEED STATEMENT

The way electricity is generated today is very different than sixty years ago. In the past, there were two basic ways of creating electricity. One was to burn fossil fuel (Coal or Oil) in a boiler, generating steam, and use the steam pressure to turn a turbine that would turn an electrical generator. The second was to build a dam and use the water pressure to spin a water turbine and generate electrical power.

Electrical generation has changed in so many ways in just sixty years. We still use Fossil fuel-powered boilers and Hydroelectric dams that create electricity. Throughout the past sixty years, we have developed environmentally friendly ways of creating electricity. These new ways of generating power are Solar panels, Wind turbines, Thermal energy, Nuclear power, and Tidal generated electric power. There is an unseen problem with all of these new ways of generating electrical power, the system can create more power than we can use, or not enough. When we have a windy/sunny day our windmills and solar panels will be producing 100% of their power-producing capability. This is a quality problem that needs an intelligent solution.

Renewable energy solutions are vital to the planet's health. These new types of energies do not operate 24 hours a day. They operate intermittently, meaning if they're driven by sunlight, they’re going to be operational 12 hours a day at best. And if you’re relying on ocean tidal currents to generate power, the tide rises and falls twice a day. This fluctuating supply of power is why we need to be able to store energy. Storing power will allow our demand to match our supply. As I mentioned in the overview statement there are many ways of storing energy. Here on the coast of California, we have an abundance of salt water (Pacific Ocean) and mountains near the ocean. This makes it an ideal location for Pumped Hydroelectric Storage. Pumped Hydroelectric Storage is ideal for this type of location. Once you install a system and apply proper maintenance, it should last for hundreds of years. The system is simple in design and is already being practiced here in the US. The location is called, Bath County Pumped Storage and is located in Virginia, with an output of 3,003 MW capacity and was completed in 1985. Pumped Hydroelectric Storage is the best solution for California’s coastline.

DESIGN AND CONSTRUCTION

The design of a Pumped Hydroelectric Storage System depends greatly on its geographic location. When choosing a suitable location for a Pumped Hydroelectric Storage System one must consider the following parameters; the distance to a water source, whether there is ample room to build the hydroelectric facility, and is there enough elevation between the pump station and elevated reservoir for adequate hydroelectric generating.

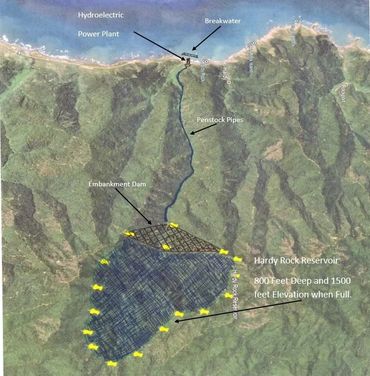

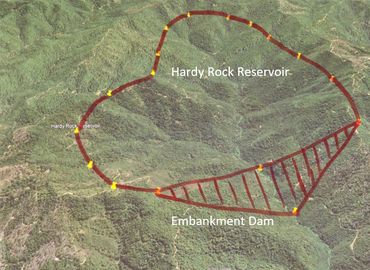

I have researched a suitable area above San Francisco CA just north of Fort Bragg. The area is known as Hardy Rock. Hardy Rock would be an ideal location for a Pumped Hydroelectric Storage location. It lies directly on the coast and two miles inland is a bowl-shaped mountain suitable for a reservoir and earthen dam. The peaks of the mountain are 1700 to 2100 feet with deep ravines. The area between the proposed earth dam and coastline has only one inhabitant. If a dam were to be built, the resident would be asked to relocate or assume the risk of remaining. All areas between the dam and coast should be void of human inhabitants and left in their natural state. Google earth was used to assess this location. Now that we found a suitable location for the Pumped Hydroelectric Storage facility, extensive geological studies will be necessary before construction begins. When all studies are complete (environmental and geological) work can begin.

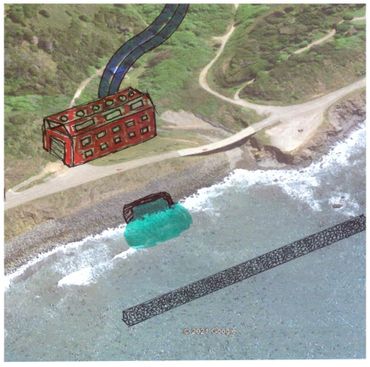

The main components of a pumped hydroelectric storage facility are the reservoir, upper and lower, and the pump/generator station. Our hydroelectric power plant differs from most because our lower reservoir will be the Pacific Ocean. The hydroelectric facility will need uninterrupted access to the ocean water. This can be done by creating a breakwater barrier just offshore and a water canal from the ocean directly to the pump/generator station. The offshore barrier will diffuse ocean wave action from causing damage to the pump/generator station. The canal connecting the ocean to the pump/generator station must supply an adequate amount of seawater to the pumps. The canal must be able to handle the discharge water from the hydroelectric generators while operating at full power. The hydroelectric power plant itself will be located near the ocean. Directly beneath the power plant will be the water turbines. The turbines will be activated via water pressure from the upper reservoir. The turbines will spin a generator that is connected by a common shaft. The generator will create electricity and supply it to the transformer. The transformer will increase the generated voltage and send it over transmission lines to be used elsewhere.

The upper reservoir and penstock are the final parts of our pumped hydroelectric facility. The reservoir is a large artificial lake used as a source of water for the turbine generators. The penstock referred to are the pipes that connect the reservoir to the generators. The turbine generators have two functions. First, they will be used to generate electricity. And second, to be used as pumps to replenish the upper reservoir water. To summarize how a pumped hydroelectric facility operates, the upper reservoir acts as if it were a battery that stores energy. When we have an excess amount of electricity, from solar panels or wind generators we send the excess electrical power to our pumped hydroelectric facility. The excess electricity will be used to pump water to the upper reservoir. The water in the upper reservoir is now considered stored energy. When we need electric power at a later date, we can release the water from the upper reservoir and generate the required electricity.

WATER PSI

Water/H2O is one of the most unusual substances found here on earth. If someone were to tell you they were as ordinary as water, well I would say they must be a really fascinating person. Water is the only substance on earth that is in all three states of matter, solid, gas, and liquid. Water also has many unusual characteristics such as; it freezes at 0°C and boiling at 100°C. Water can absorb and store a lot of heat energy without changing its state. The fact that water is a very heavy compound at about 8.34 pounds per gallon also makes it ideal for stored energy systems. Now elevate a column of water 1200 feet above its source. What you have is a pressure of about 520 psi or (pounds per square inch) at the bottom of the column.

The way you calculate how much water pressure will be in a water column is by multiplying the height of the column times 0.433. If your water column height is 1200 feet high you would multiply it by 0.433 that sum will equal 519.6 psi. This weight or pressure of water is what does the work in a hydropower plant. This water pressure created by the elevated reservoir drives the hydroelectric generators. And that’s what makes water and its unique properties ideal for pumped hydroelectric energy storage.

WINDMILL WATER PUMP

Moving water from a lower reservoir to an elevated reservoir requires energy. How efficient is pumped-storage hydroelectricity? If you take into account evaporation and conversion losses 71 to 85% of the electrical energy used to pump the water into the elevated reservoir can be regained. When motion is created, the energy required for that motion will be greater than the action of the motion itself. For instance, if it cost 1 dollar to pump 200 gallons of water up to an elevated reservoir, when you release the water back to the lower reservoir through a turbine generator your return will be about 85 cents. That loss is due to electrical and mechanical conversion and is considered a small loss by today’s standards. Windmills that are designed to generate electrical power are the technology of today. But not so long ago windmills were designed to pump water out of the ground using only the wind itself. The windmills of the past used only mechanical power to do the work. If we used today’s electric-generating windmill to pump water out of the ground, it would be less efficient than it was 100 years ago. This is due to conversion losses. Going from mechanical power to electrical power and back to mechanical power is wasteful.

I designed a mechanical water pump driven solely by wind power. This type of pump would be used in conjunction with conventional electric water pumps. Mechanical water pumps would move water to the elevated reservoir directly. The electric water pumps would also double as power generators when water from the elevated reservoir was released to the lower reservoir. The mechanical water pump design consists of a crankshaft, cylinder, pistons, and valves. The pump piston will move up and down in a vertical motion. On the down stroke vanes will open on the top of the piston allowing water to fill the cylinder. When the piston begins the up motion the inlet vanes will close and the piston will push the water up and out through the top of the cylinder. A check valve will be located on top of the cylinder preventing the water from flowing back to the piston on the down stroke. The pistons will be connected to a crankshaft by connecting rods. The crankshaft will have an axial rotation. The motion of the crankshaft will drive the piston up and down pumping water with every stroke. The windmill will be connected directly to the water pump crank shaft using mechanical linkage. No illustration of this pump has been added but will be supplied at a later date.

MATERIALS SOURCED FROM THE INTERNET

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.